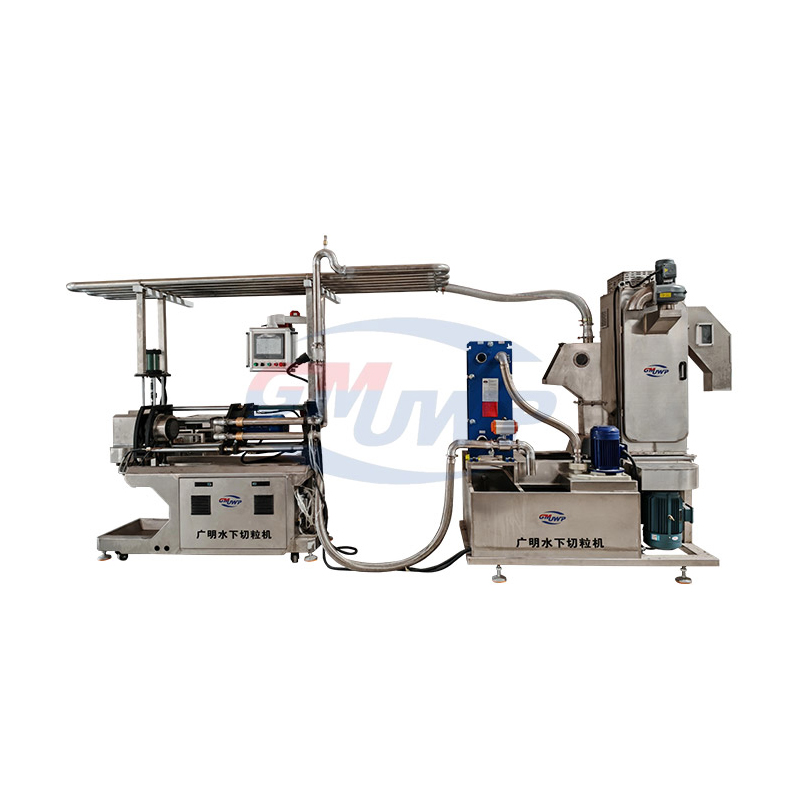

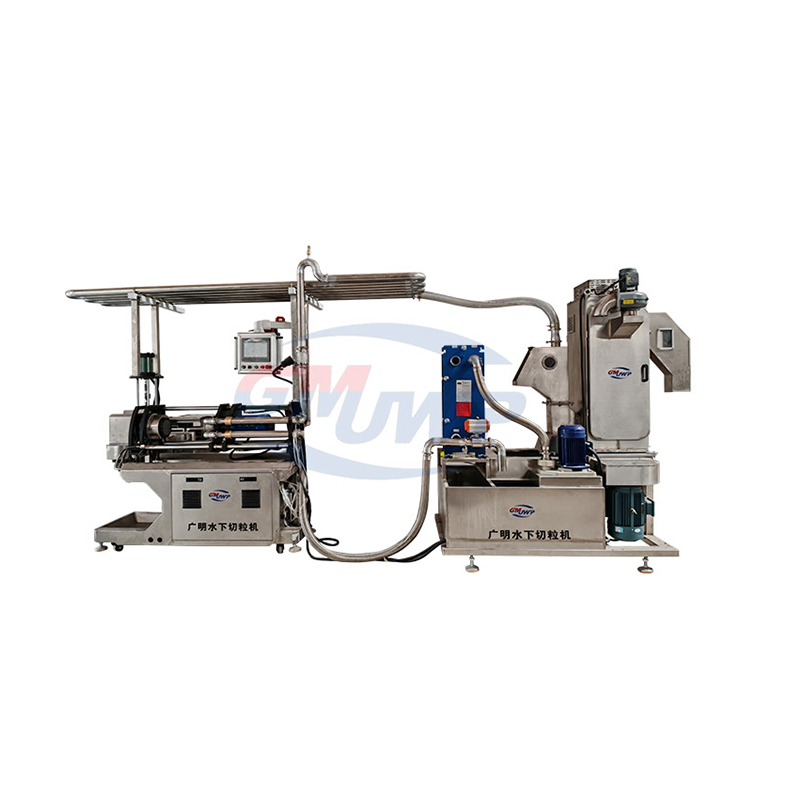

When an underwater pelletizing verification machine is operating, the high-temperature molten material is completely immersed in a flowing cooling water environment as it exits the die.

- +86-13549203718

- 405750452@qq.com

- Room 305, Building 2, No. 101, 1st Street, Langbei Xinwei New Village, Changping Town, Dongguan City, Guangdong Province